Inspection Services

Apogee Manufacturing Solutions LLC utilizes a comprehensive suite of inspection services designed to ensure your parts or assemblies meet the most rigorous standards. We integrate critical dimensional inspection as part of our in-house risk mitigation strategies, offer first article inspection (FAI) services on parts machined in-house and provide inspection services for customer supplied parts.

We go beyond simply checking a box by offering a meticulous and multifaceted approach to ensuring every component meets your exact requirements.

Inspection is a detailed and exhaustive verification process whereby features of a part are interrogated and compared to the acceptable values contained in a drawing, model or specification. Inspection can be visual, dimensional, or functional and is customizable based on the customer’s needs and detailed specifications.

Apogee has a multifaceted approach to inspection with methods that encompass various techniques, ensuring each part is evaluated from every angle:

- Visual Inspection

- Dimensional Inspection

- Hardness, Mechanical, Thermal & Functional Inspection

Spec Table

Down to 0.0001″

AS9100D

ISO 9001:2015

Coordinate Measuring Machine (CMM)

MicroVu Vision System

Ultrasonic Thickness Gage 0.003″ – 20″ (Material Dependent)

Inspection Methods

Meticulous visual assessment is integral in risk mitigation during both prototype production and longer production runs. A trained inspector’s keen eye can detect even the subtlest imperfections, like surface irregularities, blemishes, or inconsistencies in finish thereby ensuring manufacturing integrity and high quality parts.

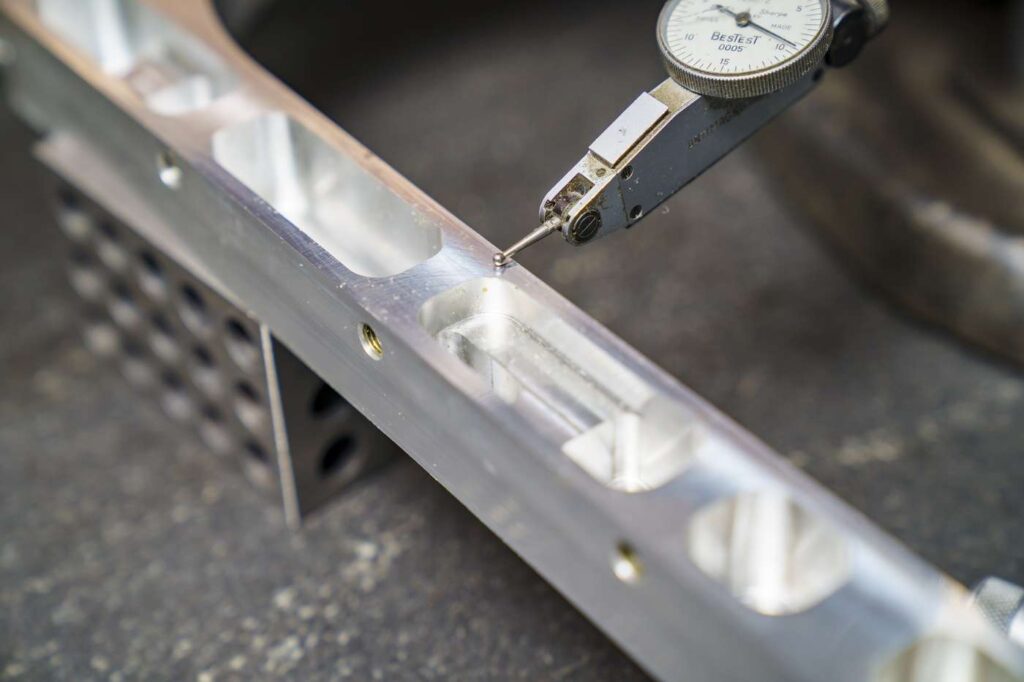

This core aspect verifies the precise measurements of a part, ensuring they align perfectly with the specified tolerances. Apogee utilizes a diverse range of calibrated and NIST traceable equipment for this purpose, including gauge pins, thread gages, calipers, micrometers, profilometers, ultrasonic thickness gauges, optical comparators and coordinate measuring machines (CMMs).

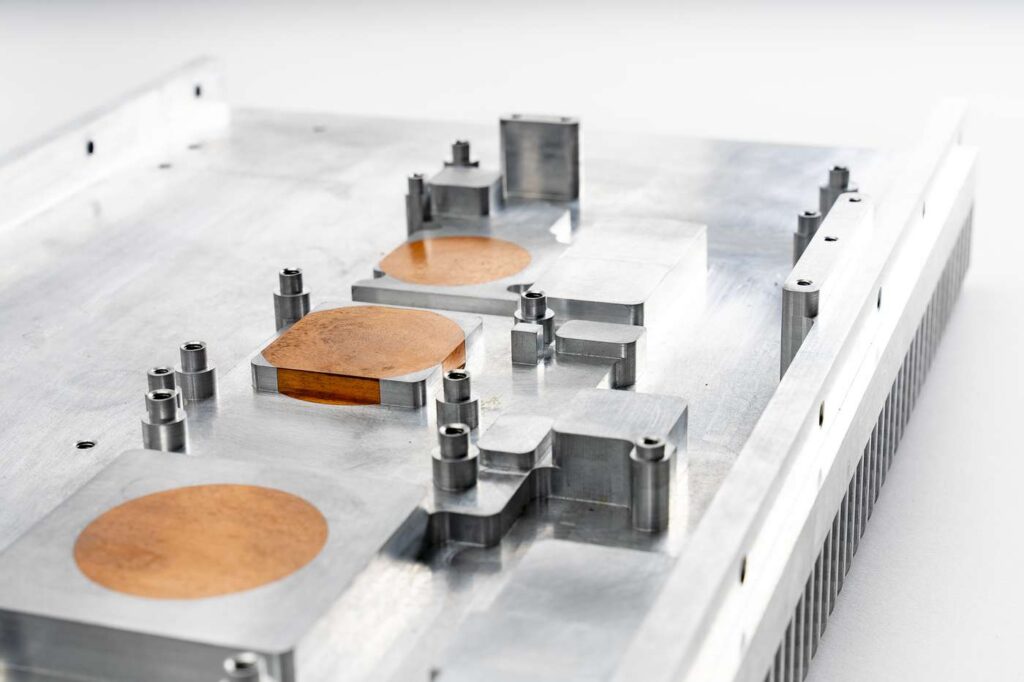

For parts with hardness requirements, thermal components or specific functionalities, Apogee employs specialized inspection procedures to ensure they operate as intended. This may involve coupon tests to verify hardness per Rockwell Scale C, thermal or mechanical performance investigation, or simulating real-world operating conditions including fatigue, stiffness and displacement.

The Power of Precision: Advanced Inspection Technologies

Apogee goes beyond conventional methods, leveraging cutting-edge technologies to achieve unparalleled accuracy and efficiency in its inspections:

- Coordinate Measuring Machine (CMM) Inspection: Apogee leverages the latest technology from Hexagon’s Measurement Intelligence Division for dimensional inspection. Specifically, our Hexagon Romer ArmTM provides very high accuracy (.0003 inch) inspection results in a portable form factor – which is perfect for measuring parts while still in CNC machines. This verification at the source is essential for reducing waste, down-time, and the inefficiency of removing/reinstalling parts throughout the machining process.

- Vision System Inspection: For inspection of smaller geometry (less than 0.001 inch), Apogee utilizes a cutting-edge optical comparator equipped with the latest MicroVu software, InSpec. Apogee’s MicroVu is an essential tool for the inspection of small punch and die features, fine geometry for complex components, cutting and abrasive tool inspections, part surface features, extrusion internal geometry and more.

- Ultrasonic Thickness Gage: For the non-destructive testing of embedded materials, Apogee utilizes an ultrasonic thickness gauge to measure material thicknesses between 0.003 inches and 20 inches (up to 0.0001 inch resolution).

Reverse Engineering

Apogee’s inspection capabilities extend beyond verifying existing designs. By combining our engineering expertise with advanced equipment and industry-leading software like SolidWorks and Hexagon’s PC DIMS, we offer seamless reverse engineering services. Our engineers can meticulously recreate your products in a digital format (drawings and/or models) to facilitate future production or replication.

Quality Is The Apogee Difference

Leading companies entrust their projects to Apogee due to our unwavering commitment to quality. This commitment is evident in several key aspects:

- Rigorous Certifications: Apogee adheres to the demanding standards of AS9100D and ISO 9001:2015 certifications and trains our inspectors in GD&T and interpretation per AMSE Y14.5. These internationally recognized certifications demonstrate our dedication to a robust quality management system, ensuring consistent excellence throughout our operations.

- Strategic Quality Integration: Apogee strategically incorporates quality verification throughout the entire production process. This at-the-source verification approach minimizes potential issues at the earliest possible stage, providing the opportunity for corrective action implementation as needed.

- Calibrated and Traceable Equipment: Apogee prioritizes the use of calibrated and NIST traceable inspection equipment at critical junctures throughout the machining process. This ensures the accuracy and reliability of measurements, providing a solid foundation for quality control.

- Comprehensive First Article Inspection (FAIs) Reports: Apogee understands the importance of clear communication. We provide detailed and easy-to-understand dimensional inspection reports for your engineers, quality departments, or clients. These reports offer complete transparency and a clear understanding of how each part measures up to the designated specifications and are compliant to the rigors of AS9102.

Apogee’s inspection services offer a comprehensive and reliable solution for ensuring the utmost precision in your parts. Our commitment to quality, advanced technology, and strategic approach set us apart as a trusted partner for even the most mission critical projects. From meticulously verifying dimensions to seamlessly recreating missing designs, Apogee will help you to achieve the highest levels of precision for your specific application.

Contact Us

"*" indicates required fields