Precision Engineering & Advanced CNC Machining Solutions

Specializing in challenging machined parts and precision tooling for aerospace applications, enhanced by state-of-the-art inspection and dimensional verification to guarantee excellence.

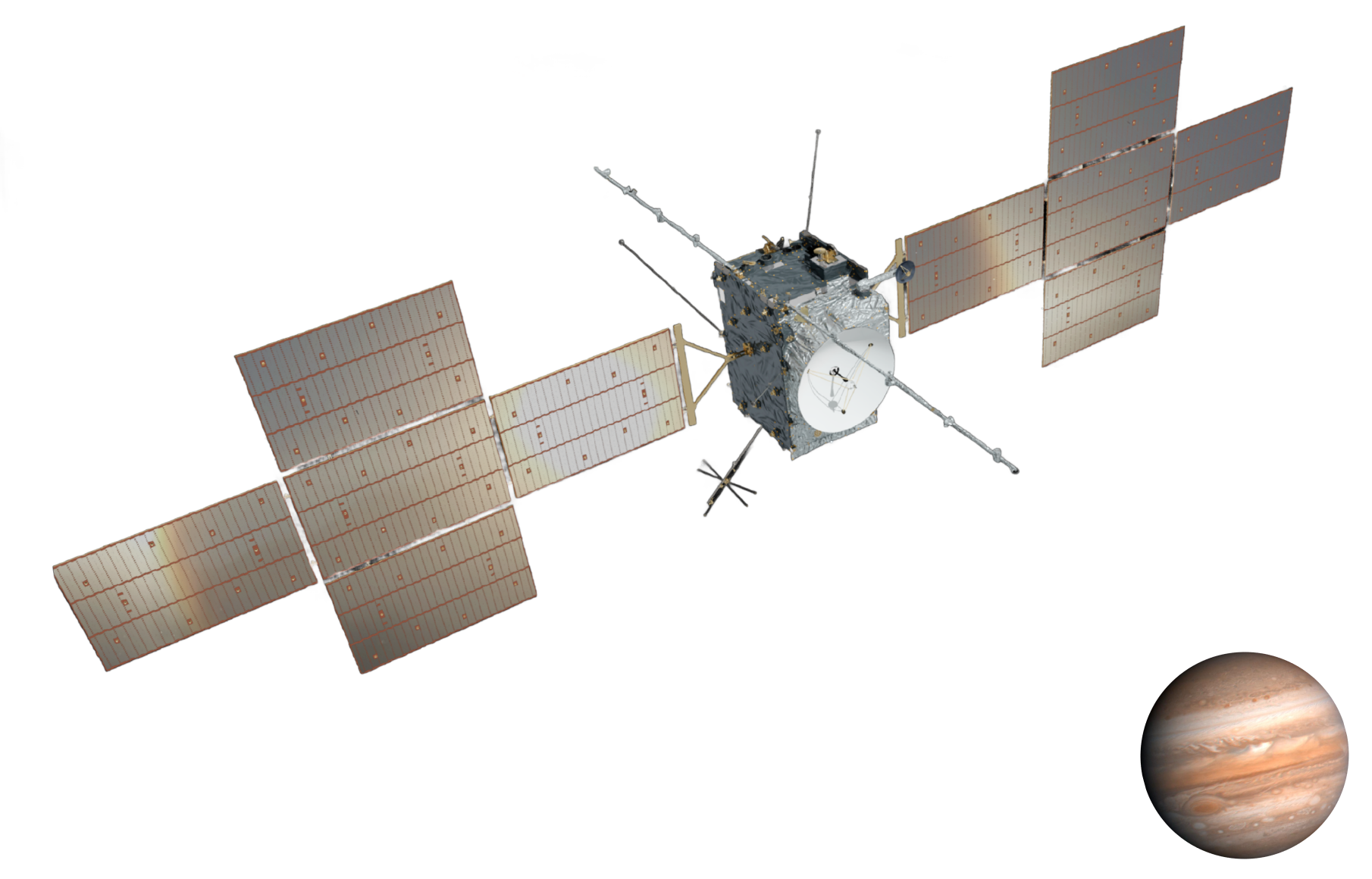

Manufactured parts for

Europa Clipper

- Aerospace

- Defense

- Telecommunications

- Pharmaceutical

- Agriculture

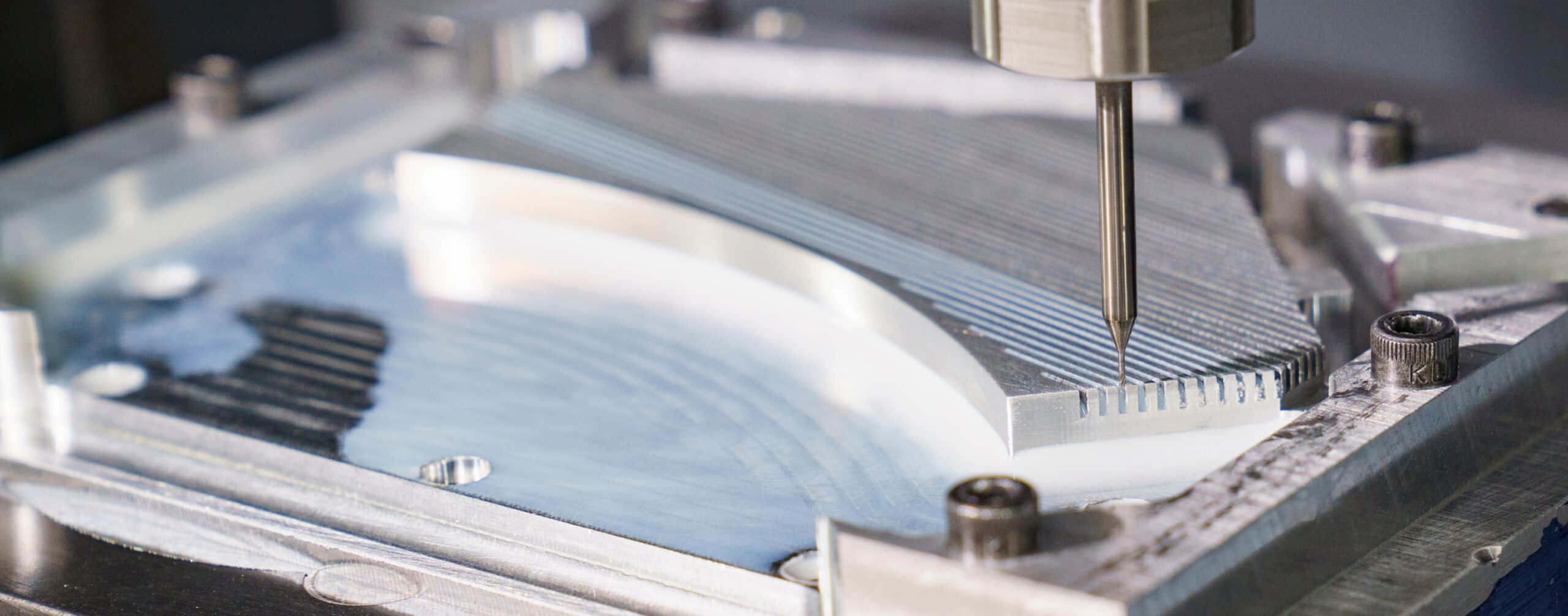

Precision CNC Machining

Our state-of-the-art CNC machining capabilities merge cutting-edge technology with the in-house expertise to deliver complex components and assemblies.

- Vertical Machining Centers for Prototyping Through Production

- Bed Mills for Tooling Fabrication & Long Parts

- Grinding for High Precision Tooling

Tooling Design

Specializing in prototype to production tooling, we cater to the exacting standards of aerospace, thermal control and automotive industries.

- 2D & 3D Path Tubing Benders

- Manufacturing, Test & Inspection Fixtures

- Heat Treated Tools for Long Life and Durability

Inspection Capabilities

Industry-leading, NIST traceable inspection capabilities, leveraging Hexagon’s cutting-edge measurement technology and comprehensive reverse analysis solutions.

- Versatile CMM Inspection Equipment

- Detailed First Article Inspection Reports

- Advanced Reverse Analysis

Value Added Services

Our value-added services extend beyond build-to-print machining and encompass all aspects of your project with design for manufactability, sequence planning and engineering support.

- Expedite Services

- Assembly and Testing

- Laser Engraving Services