Value Added Services

Apogee provides a comprehensive suite of services to propel our customers to success. Our unique and encompassing services, combined with the deployment of engineers throughout every phase of the manufacturing process, differentiates us from other companies in our industry.

Our primary services are extensively supplemented with experience driven design for manufacturability; rapid prototyping planning and execution; sequence planning; in-house secondary operations including tubing bending and mechanical assembly (including insert installation and specialized coatings); mechanical and thermal testing; and laser engraving.

Apogee Value-Added Services:

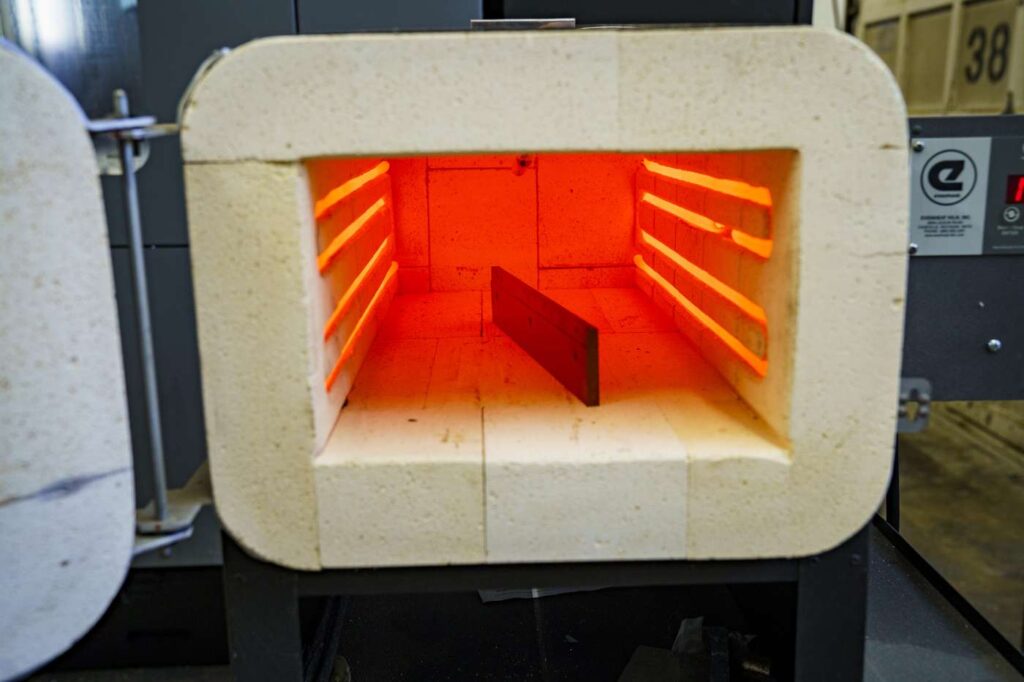

Testing is a broad category of verification in which specific performance characteristics of a component or assembly are evaluated against acceptance criteria in simulated and/or real-world applications. Examples of these characteristics include: thermal performance; fatigue life; assembly level stiffness; form and fit; environmental exposure survival; and more. Apogee has extensive experience in the design, fabrication, and operation of test fixtures. Specific test fixture examples include: thermal performance (radiation, conduction, convection); thermal cycle; proof and burst pressure; freeze/thaw; oscillating displacement fatigue life cycle; and centrifugal acceleration.

Fiber laser engraving is the process by which a material’s surface is marked by a low powered laser beam directed through a modified fiber optic cable. Apogee utilizes this technology for part identification and serialization and to create tooling instructions and guidelines. It can be deployed across a range of materials including: aluminum, stainless steel, tungsten, titanium, copper, brass, acrylic, hard plastics, silver, gold, tile, brick and marble.

Precision grinding is the process by which a material is abraded to achieve specific tolerances or surface finish. Apogee commonly employs precision grinding to fabricate specialized, high precision tooling for inspection, forming, punching and assembly. We also engage in tool and die repair and refurbishing, and blade sharpening for shears and other cutting tools.

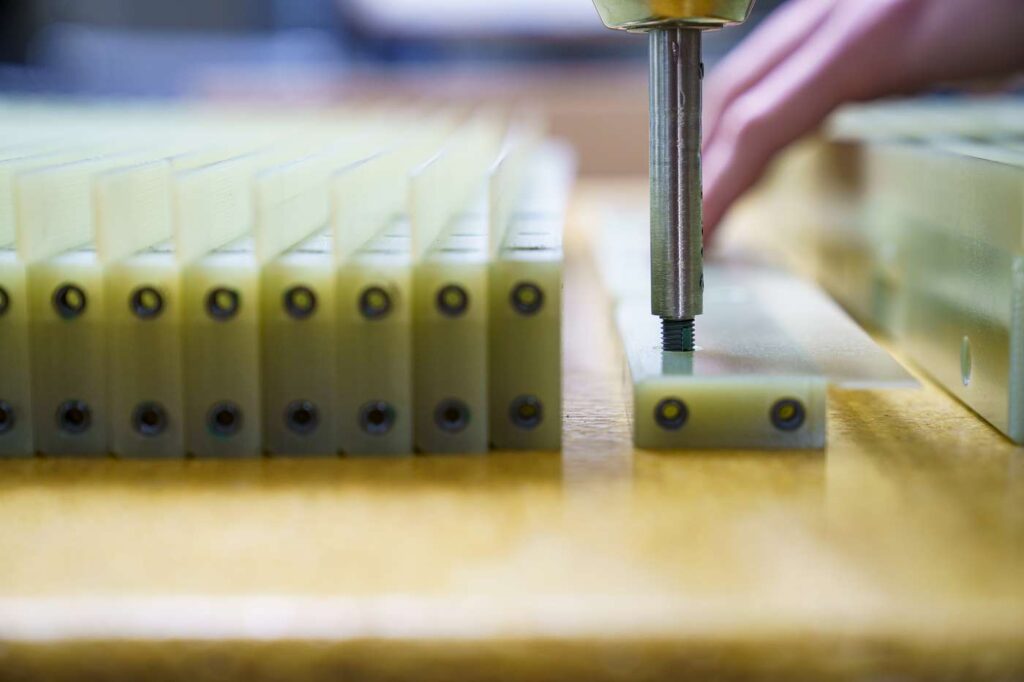

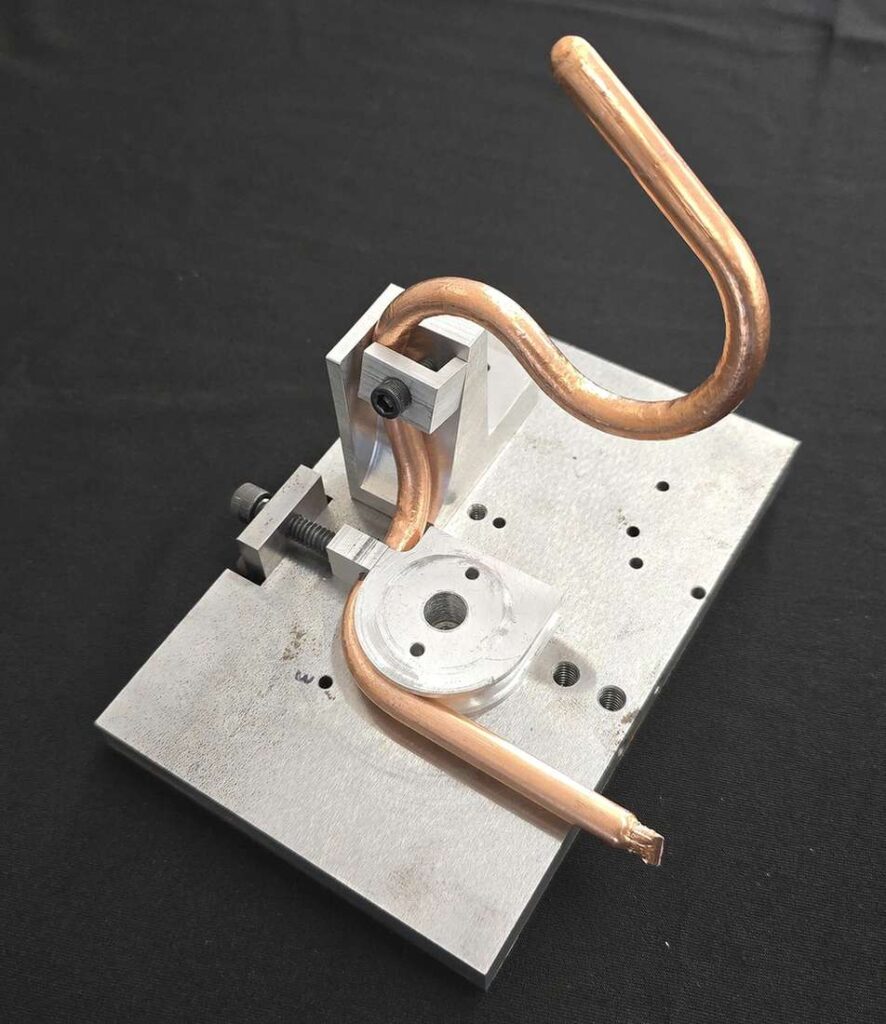

During a product’s journey up the supply chain, components are combined with other components or changed in form or appearance to create sub-assemblies and ultimately finished products. These combinations and changes occur throughout the manufacturing process and include the addition of fasteners, integration of electronics, cabling, circuits, bonding, bending, forming, coatings, and other modifications and additions. During manufacturing planning, it is often advantageous to consolidate certain processes within one manufacturing facility to improve lead time, reduce risk, and take advantage of a particular supplier’s strengths. Apogee can streamline your manufacturing processes by performing ancillary tasks in-between or after machining operations. Our skilled team is often engaged in the design of custom heat pipe benders and will bend your heat pipes and other application tubing in between machining operations to streamline production. We also stamp identification markings, apply custom coatings, and install fasteners like Standard Thread Inserts (Helicoils) and Keenserts per customer and manufacturer specifications.

Apogee offers bend-to-print services for any application including complex geometry with three dimensional paths for materials including copper, aluminum, stainless steel, steel, and titanium.

ContACT uS

"*" indicates required fields